Explosion protection: installation and maintenance

In industrial settings, the potential for explosions is a constant concern. The repercussions of such catastrophic events can be devastating, not only in terms of loss of life and property damage but also for the reputation and continuity of businesses. Thus, explosion protection measures are paramount. In this blog, we delve into the world of installation and maintenance practices that safeguard against explosions. From state-of-the-art technologies to meticulous inspection protocols, we uncover the creative strategies adopted by industries to mitigate the risks posed by explosive atmospheres.

Understanding Hazardous Environments

The first step towards effective explosion protection is understanding the hazardous environments. Industries conduct thorough risk assessments and hazard analyses to identify areas where flammable gases, vapors, or dust particles may be present. This knowledge forms the foundation for implementing appropriate explosion protection measures.

Designing with Safety in Mind

Innovative engineering plays a pivotal role in explosion protection. Designing equipment, machinery, and electrical installations with safety in mind helps prevent sparks or ignition sources from triggering explosions. Components that come into contact with explosive substances are constructed from materials that resist sparks, ensuring a safer operating environment.

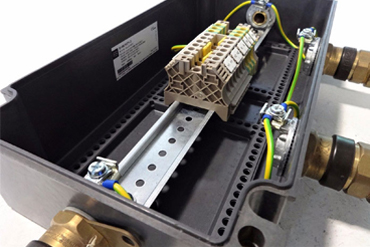

Explosion-Proof Enclosures

Enclosures designed to withstand explosions are a hallmark of explosion protection. Explosion-proof enclosures house electrical equipment and connections in areas where explosive atmospheres are likely. These specialized enclosures prevent sparks or heat from escaping and igniting the surrounding hazardous substances.

Intrinsically Safe Devices

For environments where sparks cannot be entirely eliminated, intrinsically safe devices offer an ingenious solution. These devices are designed to limit electrical energy, ensuring that any spark produced is incapable of igniting the surrounding flammable atmosphere. Intrinsically safe equipment proves invaluable in situations where other protection measures may not suffice.

Regular Inspections and Maintenance

Vigilant maintenance and inspections are the backbone of explosion protection. Regularly checking equipment, electrical systems, and enclosures helps identify potential hazards and ensures that all protective measures remain effective. Preventive maintenance mitigates the risk of malfunctioning equipment becoming a catalyst for explosions.

Training and Education

A well-informed workforce is a powerful asset in the fight against explosions. Companies invest in comprehensive training programs to educate employees about potential hazards, proper handling of equipment, and emergency response protocols. This proactive approach empowers workers to identify and mitigate risks before they escalate.

Emergency Shutdown Systems

In the event of a hazardous situation, rapid response is crucial. Emergency shutdown systems automatically cut off power to equipment or machinery when abnormal conditions are detected. These automated safety measures act as a failsafe, swiftly mitigating the potential for an explosion.

The risks posed by explosive atmospheres demand unwavering attention and creative solutions. Through advanced engineering, explosion-proof enclosures, intrinsically safe devices, and diligent maintenance practices, industries are taking a proactive stance in protecting their workforce and assets from catastrophe. By understanding hazardous environments, providing comprehensive training, and implementing emergency shutdown systems, we create a safety net that extends across industries.

As we continue to innovate, investing in explosion protection measures ensures that industries can operate with confidence, knowing they are armed with the best defenses against potential disasters. Combining creativity, expertise, and unwavering commitment, we forge a safer future in which the specter of explosions is no longer a looming threat. Together, let us build a world where the risks of explosive environments are minimized, and safety stands paramount.