Key Features to Look for in Explosion-Proof Products

In the quest for industrial safety, selecting the right explosion-proof products is crucial. When dealing with hazardous environments that pose the constant threat of explosions, these specialized tools become the guardians of security. However, with a multitude of options available, it can be challenging to navigate the landscape of explosion-proof products.

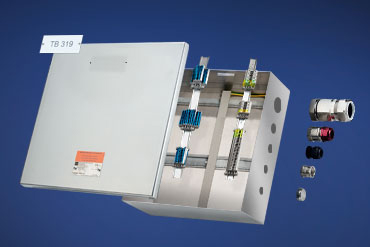

Robust Enclosures with Ingress Protection

The first line of defense in any explosion-proof product is its enclosure. Look for products designed with robust materials that are resistant to impact and corrosion. Additionally, ensure that the product has an appropriate ingress protection (IP) rating, indicating its ability to keep out dust and water. A high IP rating reinforces the product's capability to withstand harsh environments and offers added durability.

Compliance with International Certifications

A hallmark of reliable explosion-proof products is compliance with internationally recognized certifications such as ATEX, IECEx, and UL. These certifications demonstrate that the product has undergone rigorous testing to meet the highest safety standards. Prioritizing products with reputable certifications assure that they are well-suited to tackle the challenges of hazardous environments.

Temperature Class and T-Rating

In explosive atmospheres, temperature is a critical factor that can trigger catastrophic events. Pay attention to the product's temperature class and T-rating, which indicate the maximum surface temperature the equipment can reach without causing ignition. Choosing products with appropriate temperature ratings ensures they can safely operate in specific hazardous zones.

Proper Cable Gland Entries

Cable gland entries serve as crucial points of entry for electrical wiring into explosion-proof enclosures. Products with well-designed cable gland entries not only prevent the ingress of hazardous materials but also offer ease of installation and maintenance. Opt for explosion-proof products with multiple cable gland entry options to accommodate various wiring configurations.

Sealing and Venting Mechanisms

Explosion-proof products must be designed with effective sealing and venting mechanisms. These features ensure that internal explosions are contained within the enclosure, preventing flames or gases from escaping and igniting the surrounding atmosphere. Proper sealing and venting offer a vital layer of protection against catastrophic events.

User-Friendly Design and Access

In hazardous environments, ease of use is essential. Look for explosion-proof products with user-friendly design elements, such as clear labeling, accessible controls, and straightforward maintenance procedures. Intuitive design empowers workers to operate equipment confidently and efficiently, minimizing the potential for human error.

Durability and Longevity

Reliability is a non-negotiable trait in explosion-proof products. Opt for products from reputable manufacturers known for their durability and longevity. Investing in well-crafted, long-lasting equipment ensures that it can withstand the demands of hazardous environments, reducing the need for frequent replacements and minimizing downtime.

Selecting the right explosion-proof products is the cornerstone of industrial safety in hazardous environments. By considering key features such as robust enclosures, international certifications, temperature class, cable gland entries, sealing and venting mechanisms, user-friendly design, and durability, industries can fortify their defense against potential explosions.

In the pursuit of optimal safety, embracing top-notch explosion-proof products not only protects lives and assets but also bolsters the confidence of workers and management alike. As industries continue to prioritize safety, the key features mentioned above serve as guiding beacons, illuminating the path to a safer, more secure future in hazardous environments.